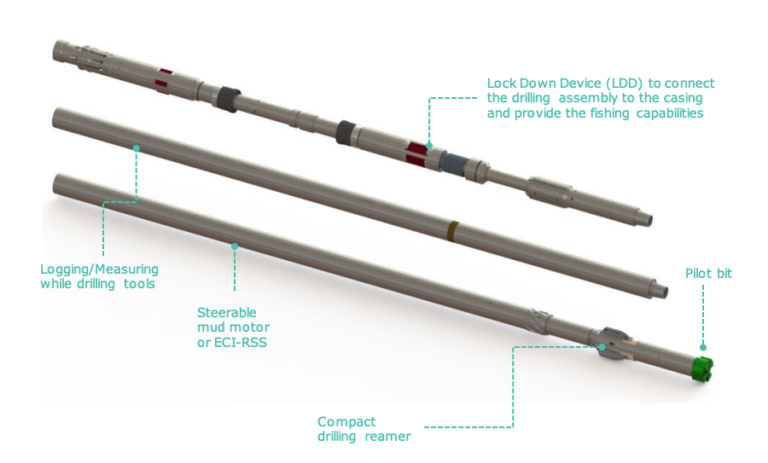

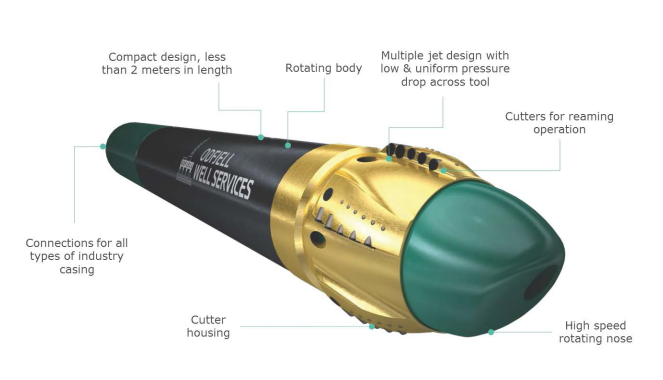

Odfjell Well Services offer the latest Casing while Drilling (CwD) technology, including our Enhanced Casing Installation (Retrievable CwD) System and our range of Advanced Casing Deployment Tools (REACH CwD motors and high performance DEFUSE reamers).

OWS can offer a variety of CWD solutions to overcome the most problematic formations and well paths.